The machines for elevators with crown, worm gear, and gears were until the 20th century the most reliable and efficient vertical transport solution for any type of elevator.

In 2000, with the incorporation of gearless machines and permanent magnets, this trend began to change, as the new machines are smaller, consume less energy and their engineering is more flexible for any type of project, allowing the machine for your next elevator is much smoother, smaller and quieter.

An example of this change in trend is the number of projects that GOLD Lifts are installed with a gearless machine, 10 years ago only 20% of lifts were installed with this type of solution, currently more than 60% of the equipment uses this type of engineering for your solutions.

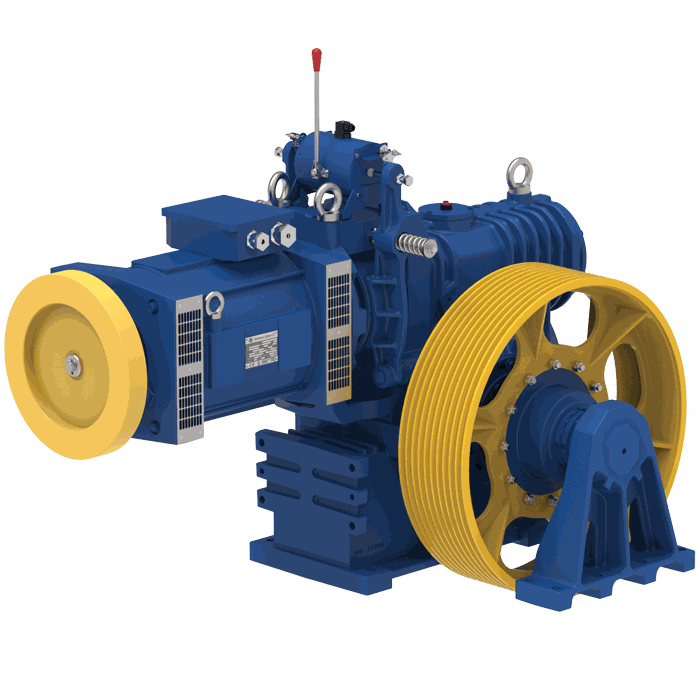

What is a machine of gears (Gear) with a synchronous motor?

The machines with gears (GEAR) and reduction motors, generally have induction motors, where the torque is generated by the application of an alternating current (AC) to a geometrically distributed three-phase wiring, whose name is stator.

The induced current creates an electromagnetic surface on the rotor, the interaction between the startors and the rotor creates the mechanical torque that results in the rotation of the rotor.

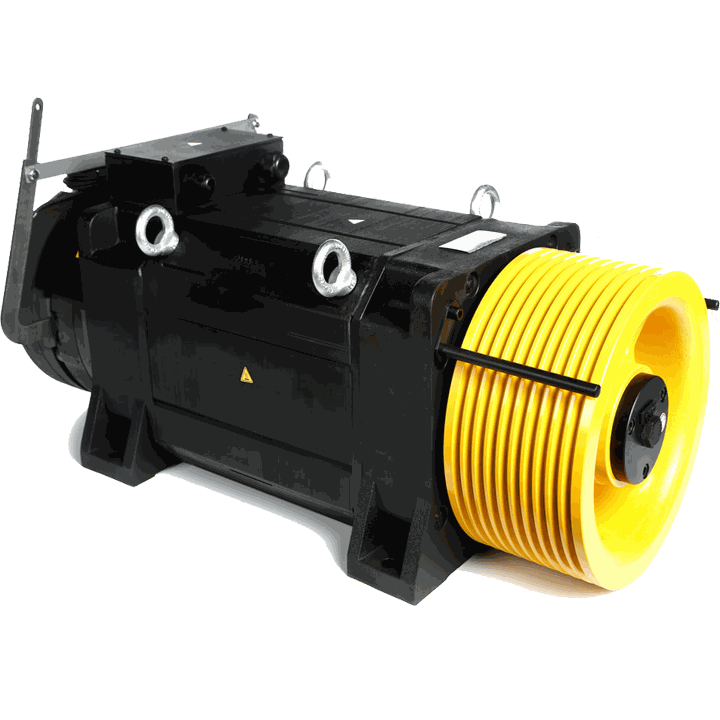

What is a gearless machine with a synchronous motor?

1. The machines are smaller because the energy transfer is direct to the elevator pulley, this means that it does not require a system (crown and worm) that reduces the RPM to the necessary speed of the elevator.

2. Synchronous machines allow greater energy savings since the permanent magnets join together to make the movement synchronously with the stators.

3. It does not require lubricating oils, since as it does not have gears, the energy transfer is made directly to the pulley.

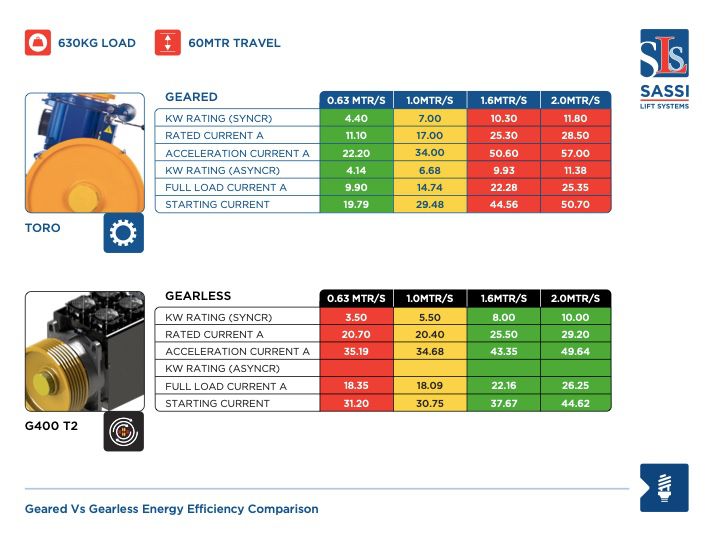

What is the difference between a machine with gears and a machine without permanent gears?

As we have seen previously, the movement of the rotor is the product of the interaction between the stator and the rotor, the speed at which the rotating magnetic surface and rotor rotate is asynchronous since the rotor does not rotate at the same speed as the magnetic surface, This is due to the fact that in the event that this surface will move at the same speed, it would not have a change in the polarity of the rotor and therefore, there would be no movement in the machine.

Las 2 principales diferencias que tienes que saber entre las máquinas con engranajes (gear) y las máquinas sin engranajes (Gearless)

Know the differences between elevator machines.

Ascensores Camilleros Equipo nuevo